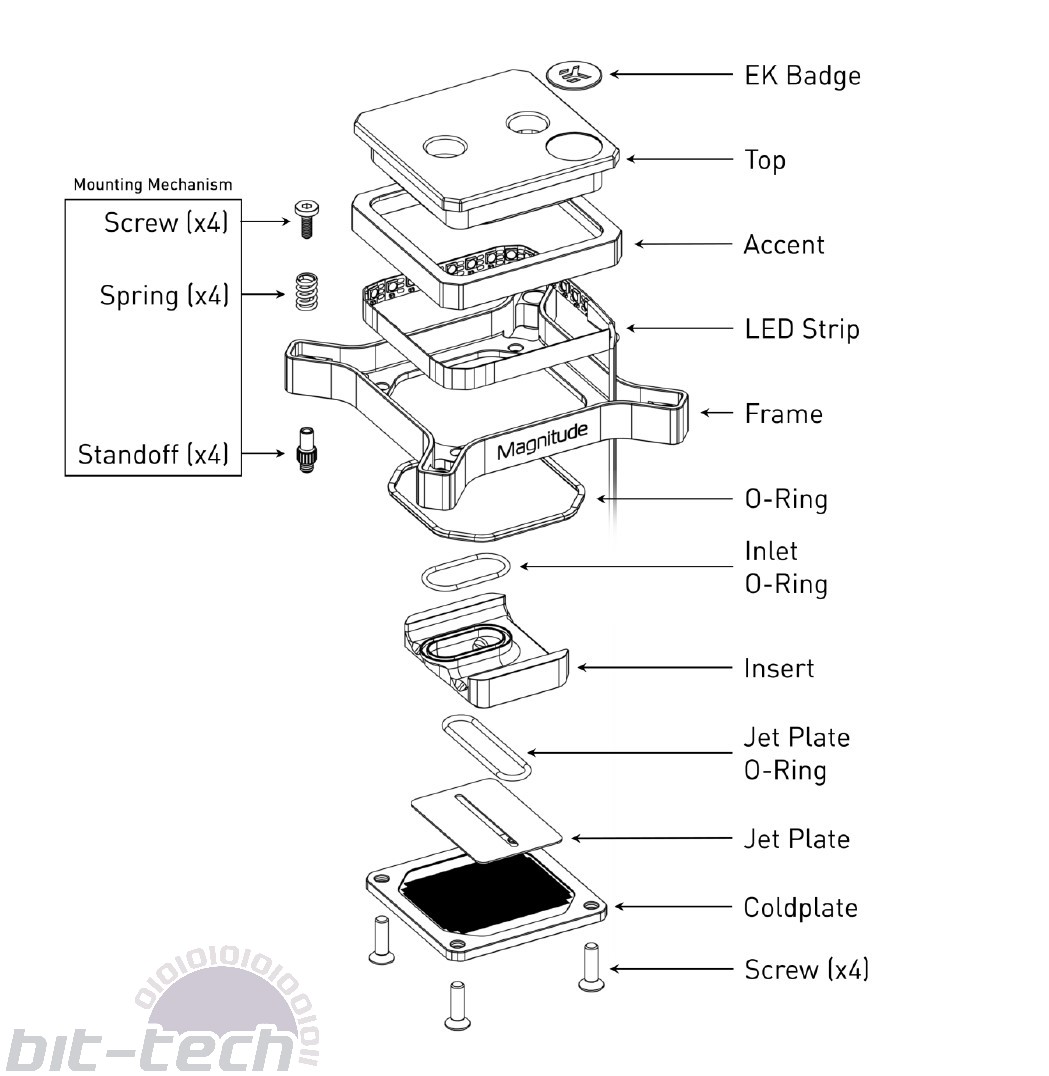

Construction

EK chose to begin largely from scratch in regards to the design behind Magnitude. The block itself is divided up into a few key elements:

- The block top

- The aesthetic accent ring

- The mounting framework

- A brass insert

- A thin steel jet plate

- The copper coldplate

Starting with probably the most noticeable external feature, we have the mounting frame. Previous blocks have used a sheet steel bracket to attach the block to the CPU socket. This is very much an industry standard with the majority of blocks on the market using something similar. Magnitude, however, features a solid, machined aluminium frame that wraps around the outside of the block. This makes for a bold design choice, likewise thumbscrews have been eschewed in place for low profile custom screws which sit above springs, yet below the surface of the frame. As with previous mounting systems, the springs ensure even mounting pressure across the CPU, having them out of sight though in a low profile package is rather pleasing. The frame's shape won't be for everybody, but personally I really like it. Since it's machined from a solid piece of aluminium, it has a very tactile, sturdy feel to it. The finish is matte and anodised in either silver or black, with the part being aluminium there's perhaps also potential to have them anodised in other colours.

The next part that's easily noticed is the accent ring. Again like the frame, they're machined from solid pieces of metal, not injection moulded like the rings on the Velocity blocks. The coloured variants are cut from aluminium, whilst the nickel plated rings are cut from brass, there are also acetal rings and a DRGB one too. The blocks at release come in standard arrangements of acetal, nickel and plexi finishes and sport the regular black, white and nickel accent rings. That means unfortunately if you want to fit your block with say a vivid blue one, you'll have to purchase that separately. It's also worth noting that these rings don't come into contact with the coolant, they simply sit outside the main block itself.

Looking at the block tops, things are somewhat familiar to before. They're square with two G1/4 ports and currently come in nickel plated brass, plexi and acetal finishes. One departure from velocity is the port placement, however. Thanks to using an insert beneath, the ports are no longer placed asymmetrically on the block. This is a small thing but honestly, I'm rather happy to see it. There are a couple of advantages, the first being that it simply looks better (subjective I know, but it's hard to argue in favour of off-centre holes), the second is that it gives ample room for larger fittings. EK opted to use the same 29mm port spacing found on their Vector GPU blocks, so if you're keen on the parallel trend that's sweeping the scene, this will be welcome. It's worth noting that the nickel top completely covers the accent ring, so there's no point in purchasing a DRGB accent piece to use with it. For this reason, the Full Nickel blocks ship without any RGB strips.

Speaking of RGB strips, the DRGB plexi versions come with a 30 LED strip installed, which you can plug into your motherboard or DRGB controller of choice. Whilst we didn't test the lighting on the block in this case (it was more of a performance test session), we did briefly fire up the LEDS on their own straight off the motherboard header on our test system. Yikes those things are bright. 30 LEDS is perhaps a bit overkill for such a small block, but there's no real sense in complaining about that, it's simply very bright. Heck I should probably pick up some of those strips for distro plates as the light density is very impressive.

One of the big departures for this block is the brass insert. This is one of the meaty changes as this insert redirects the coolant flow and is largely responsible for how the blocks differ. The insert itself is machined from a solid block of brass in a pair of operations, it has EPDM o-rings on both the top and bottom to ensure liquid doesn't seep between it and the other block elements. By changing these inserts, EK is able to prioritise coolant flow to different areas of the coldplate. The other main feature is that it seats the jet plate on the cooling fins. The jet plates are also tailored for specific platforms, with the 115X plates rocking a curved plate to increase flow over the centre of the fin stack and LGA 2066 and AM4 using a parallel plate to push coolant evenly along the fins. These plates also come in 3 thicknesses, the idea being that pressure from the insert pushes the plates down, deforming the cold plate. This deforming of the plate has been done before in their previous blocks, but now there is a great ability to customise things.

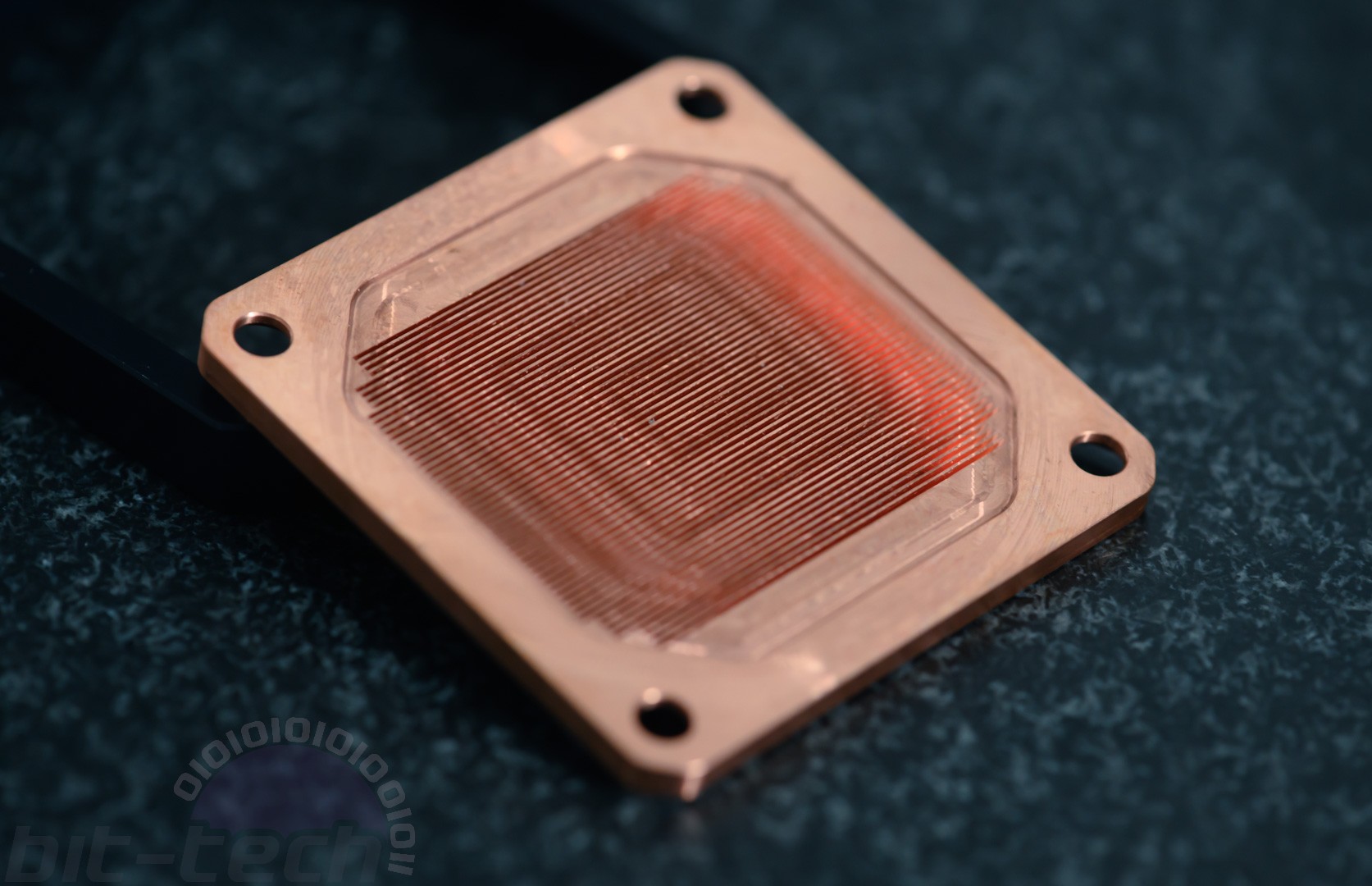

The final piece of the puzzle is the cold plate itself. The colplates come in raw copper or nickel plated, both feature a dense fin stack formed from 0.26mm micro-fins separated by 0.4mm channels. These plates have been machined as with previous EK blocks rather than skived like in Corsair's Hydro X blocks. The main change to the plates, however, is found on the underside. Rather than making the bases flat and polished, EK finished them on a lathe in order to shape the underside into a convex form. The idea here is it further accentuates the form produced by the jet plate, supposedly leading to greater contact with the IHS. It's a fairly sizeable bulge too, one can see it fairly clearly from a side-on perspective.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.